- Home Page

- Company Profile

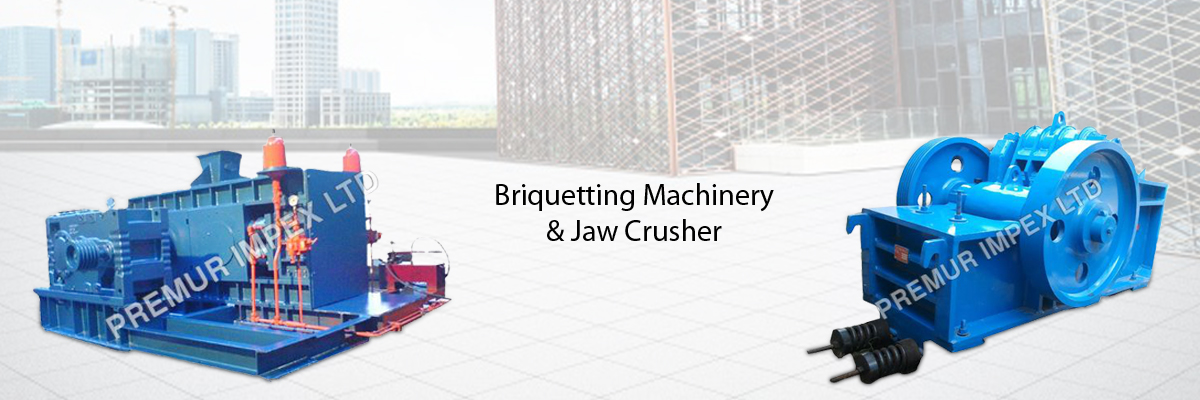

- Our Products

- Extra Links

- Our Customers

- Contact Us

Grinding MillThe offered Grinding Mill are widely used in production and material recycling industries for breaking solid substances into smaller sizes by crushing, grinding and cutting with the help of a series of heavy blades mounted on a rotating shaft which rotates with the help of a high speed electric motor which is capable to run continuously for a longer period of time. The body and the components of these machineries are manufactured by using premium grade cast iron which results higher strength and rigidity to the structure which make them capable to withstand large uneven forces and vibrations.

|

Ball Grinding Mill

- Automatic Yes

- Capacity 40-40000 Kg/hr

- Color Blue

- Computerized Yes

- Delivery Time 5-7 Days

- Material Stainless Steel

- Minimum Order Quantity 1

- Sample Available Yes

- Supply Ability 10 Per Day

- Warranty yes

Ball Grinding Mill offered by us, is specially used for grinding the nanotubes into powdered form. This machine is preferred for its high accuracy, smooth functioning, extended life span, fast speed, high tensile strength, good mechanism, removes impurities, and easy to operate. This is manufactured using premium quality raw materials and upgraded technology by our skilled workers. Ball Grinding Mill is available for our eminent clients or customers in bulk at nominal rates.

Wet Grinding Ball/Rod Mill

Price: 1200000.00 - 1500000.00 INR /Unit

- Price Range 1200000.00 - 1500000.00 INR

- Automatic No

- Capacity 500-2000 Kg/hr

- Color Gray

- Computerized No

- Delivery Time 1 Days

- Feature High Efficiency

- General Use Grinding

- Main Domestic Market All India

- Main Export Market(s) Asia, Australia, Eastern Europe, Central America, Africa, Middle East, South America, Western Europe, North America

- Material Other, Cast Iron

- Minimum Order Quantity 1

- Product Type Grinding Ball

- Supply Ability 10 Per Day

- Unit of Measure Unit/Units, ,

- Unit of Price Unit/Units

- Voltage 400-420 Volt (v)

- Weight (kg) 4-5 Tonne

Wet Grinding Ball/Rod Mill is a heavy duty grinder which is used to grind and bend various substances in various applications like paints, pyrotechnics, ceramics, mineral dressing processes and selective laser sintering. It has a large hollow cylindrical body which is manufactured by using heat treated cast iron with an enhanced tensile strength which helps to withstand large impact forces. Wet Grinding Ball/Rod Mill consist of medium to large sized metal balls that are placed inside the chamber which moves as the machine rotates. This machinery weighs around 4 to 5 tonne with a working capacity of 500 to 2000 kilograms per hour.

Application:

Applicable for grinding abrasive Ores like Graphite/Manganese/Chromite Ores in Mineral

Capacity available:

- 40Kgs/hr-4000Kgs/hr

3 Roller Grinding Mill

Price: 1200000.00 - 1500000.00 INR /Unit

- Price Range 1200000.00 - 1500000.00 INR

- Automatic No

- Capacity 500-2000 Kg/hr

- Color Green

- Computerized No

- Delivery Time 1 Days

- Feature High Efficiency

- General Use Grinding

- Main Domestic Market All India

- Material Cast Iron, Other

- Minimum Order Quantity 1

- Payment Terms Cheque

- Product Type Grinding Mill

- Supply Ability 10 Per Day

- Unit of Measure Unit/Units, ,

- Unit of Price Unit/Units

- Voltage 400-420 Volt (v)

- Weight (kg) 4-5 Tonne

3 Roller Grinding Mill is a semi-automatic machine which is fabricated by using cast iron having high tensile strength which results in longer service life. It is provided with a high performance motor which runs at a relatively higher speed at a standard alternating voltage of 220 to 415 volts with a low power consumption which results in economical operation. 3 Roller Grinding Mill is ideally designed to handle materials such as bauxite, china clay, coal, coke, lime stone, soap stone, herbs, spices etc. The rotor of the blades rotates with the help of motor through a belt transmission system which also results in smooth and noiseless operation.

Application:

Tertiary crushing of soft, medium hard and less abrasive minerals with a max output of 275 Mesh B.S.S. and upto 300 mesh B.S.S. for some soft non-abrasive materials. Suitable to handle, Bauxite, China Clay, Coal, Coke, Lime Stone, Soap stone, herbs, spices etc.

Capacity available:

- 40Kgs/hr-4000Kgs/hr

X

|

|